It all starts with a need. No matter how small it may be. I needed to have a “cover” for an aquarium overflow (to both quiet the system down and to prevent splashing). I decided to quickly design it in OnShape and print it out on my 3D Printer. Shortly after designing it and slicing it with Cura I loaded up the file into OctoPrint to realized it was a an 18 hour print. Not only was it an 18 hour print, it was so large this 18 hours was only for half of what I needed.

Clearly I needed a better solution. So why not buy one of those little CNC routers I see on Banggood.com so often? I’ve wanted to try them, and a cut like that couldn’t take more than 30 minutes right? Down into the rabbit hole I went.

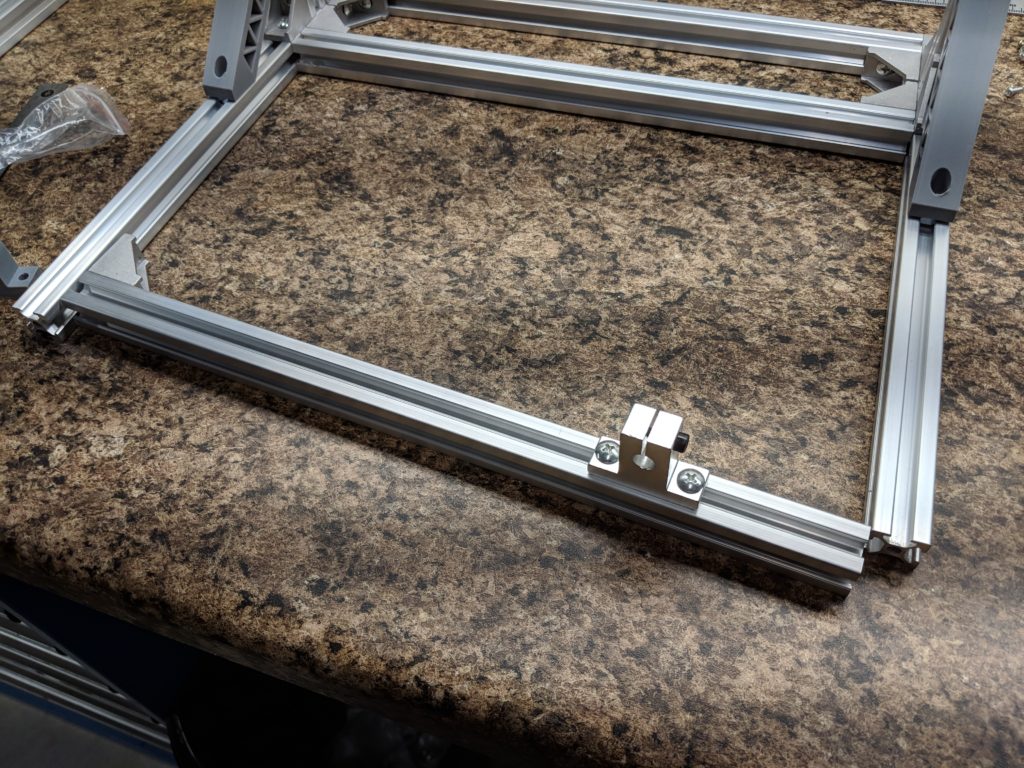

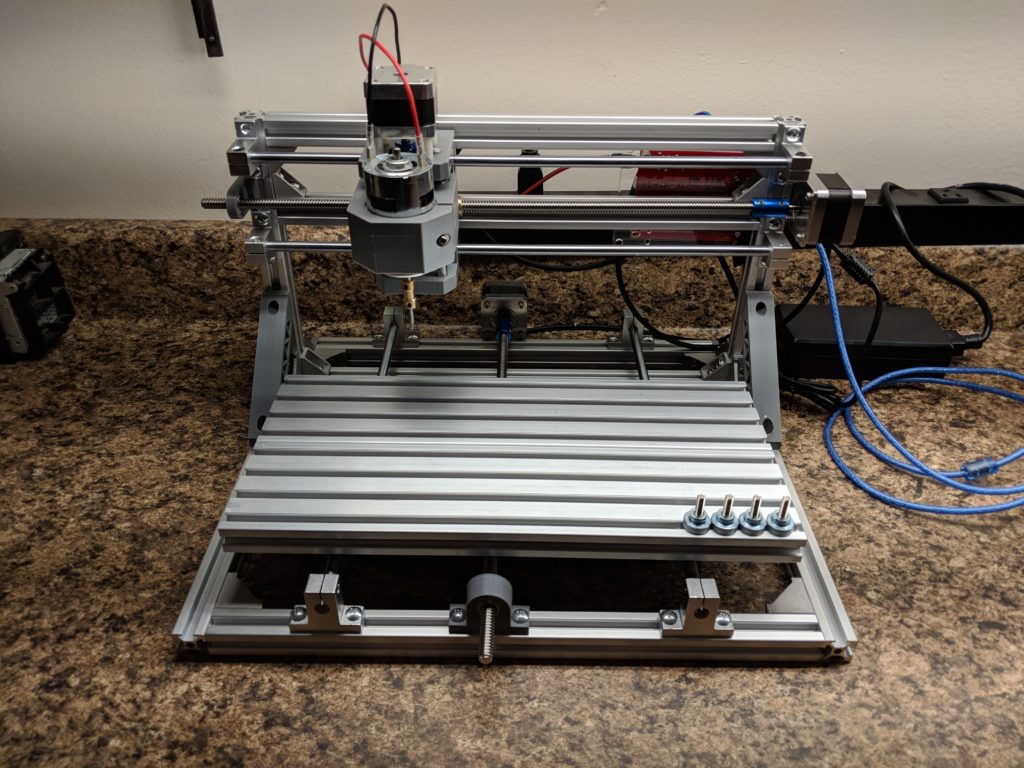

A day later I made my purchase. I decided on the “3018 3 Axis Mini DIY CNC Router Standard Spindle Motor Wood Engraving Cutting Milling Engraver” and at the end of the week it arrived. This worked out as I was very busy at work and wouldn’t be able to build it until then anyways.

I was not prepared for how much effort jumping into the CNC cutting / engraving world would take. Then add on all the faults of this 3018 Kit it would consume me for a couple weekends!

Assembly:

The Kit Problems:

- Wrong sized “SK”

- The linear rod’s are 8mm in size, and the kit comes with 8 SK’s total. 6 of them were SK8 (8 meaning 8mm), and 2 of them were SK10’s.

- Wrong threading on the lead screw.

- So this one certainly threw me for a whirl and there was no way I could over-come this without purchasing more items. The kit came with some 8mm Lead screw’s which move the x/y axis. I ran into an issue with some of the brass not screwing in. After many minutes of trying to figure out what was wrong I eventually looked at the lead screw and realized the thread pitch was different than the other.

- Wrong sized screws

- There are a few spots on the kit where the included screws were too long and thankfully I had a good set of M5 screws which got me through it.

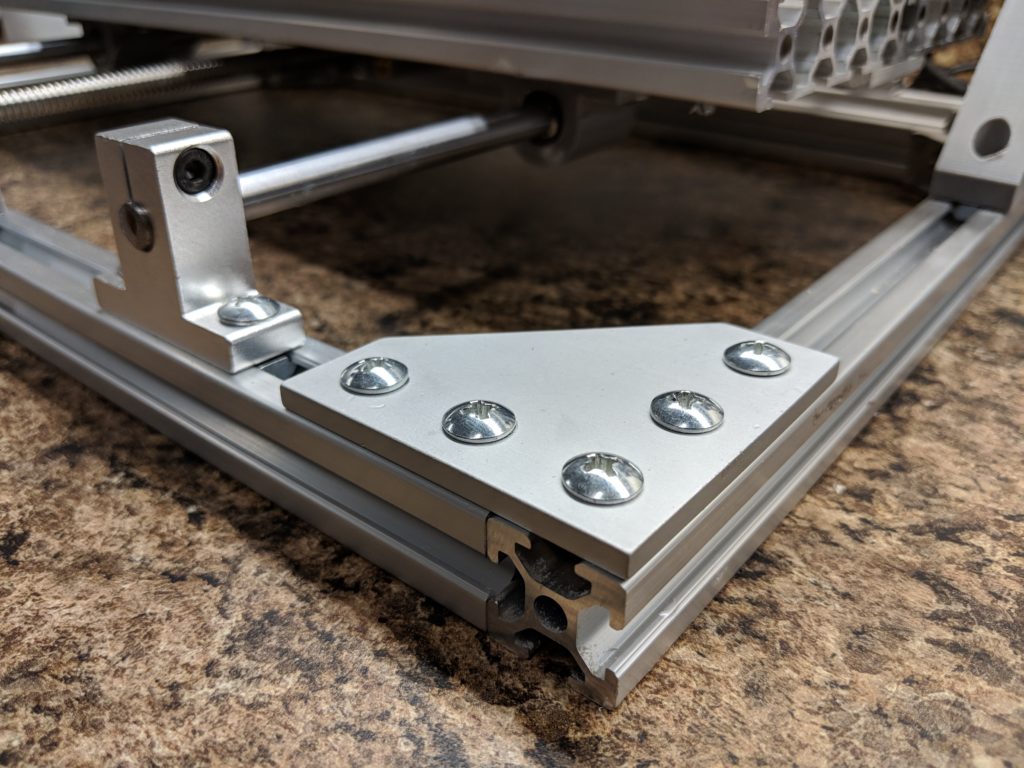

- Missing Corner Brackets

- The kit was missing 4 of the 2028 Corner brackets.

So about $45 later and amazon next day shipping I was back up and in assembly. (I did contact Banggood about these issues, and exchanged several emails and they were supposed to get back to me within 72 hours… 7 days ago.)

Update: Banggood and I have resolved our issue and they are issuing me a partial refund that I am satisfied with.

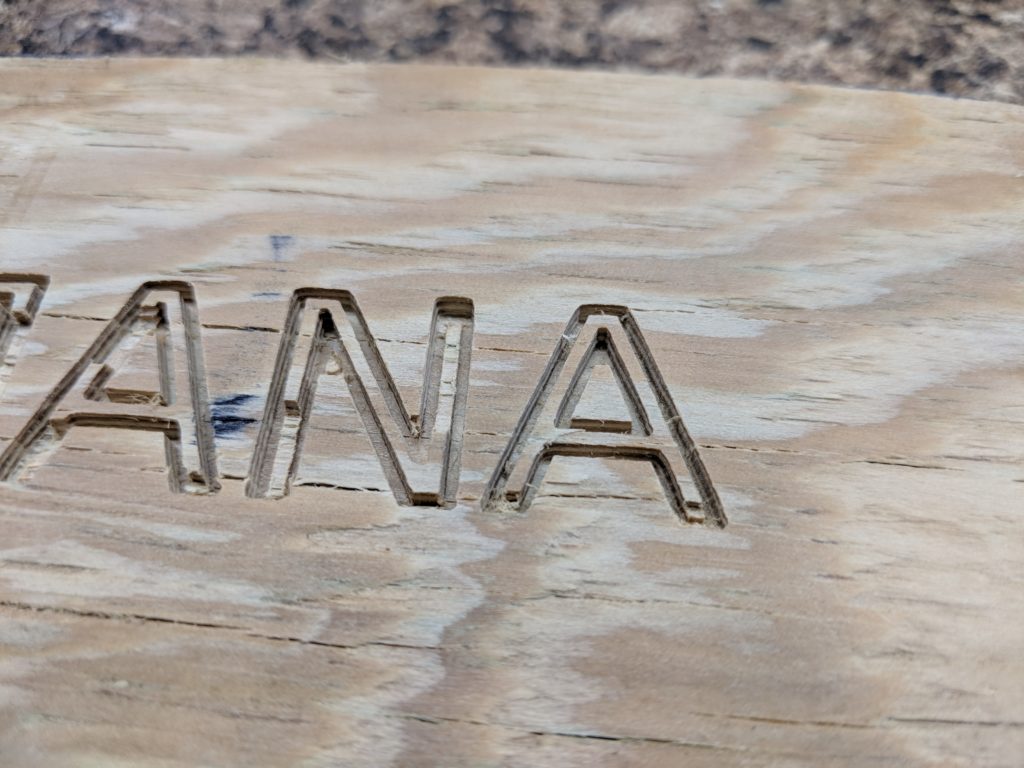

First Cuts!

After assembly I watched this youtube video “How to start CNC Machining for under $200 – Working with the T8 CNC engraver” which was tremendously helpful in learning the basics of the CNC. With this guide (and part 2 since the AutoDesk software is no longer around) I was able to get my first engraving completed.

Upgrades

Now that I have the thing up and cutting / engraving I want to push it further. I decided to do a few upgrades.

- ER11 Collet

- The set-screw holding device for the tool sucked. 100% sucks. It wobbles a fair amount and you are very limited in size of what tools you can use.

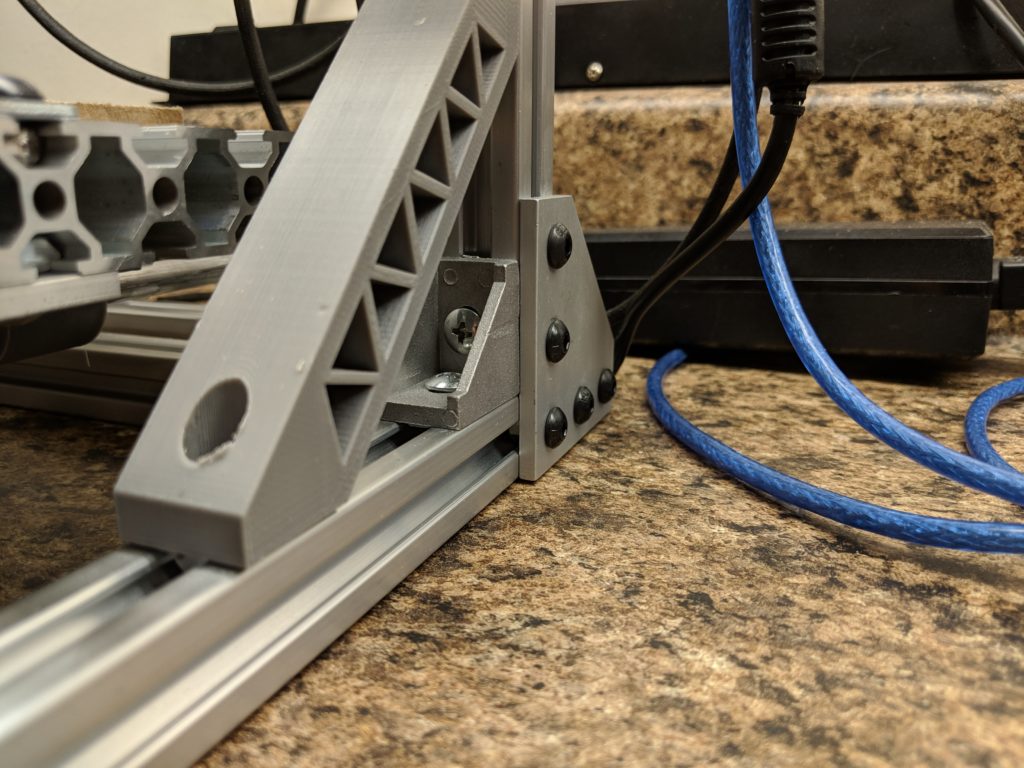

- Additional Bracing

- One of the reasons most people say you can’t cut anything significant with these cheap CNC’s are becuase of the strength. While I feel the Z-Axis is the weakest of the axis, these were low hanging fruit that I decided to upgrade.

- Material Clamps

- Bought a few cheap material clamps from Amazon. These are significantly better than the ones it comes with, but still not very good. A light weight vice may be the best solution in the future.

Future Upgrades:

Honestly I am really torn on where to go with this CNC at this point. It engraves and cuts softer materials just fine. It does require you to go pretty slowly. It could use some more vertical wiggle room, but the higher it is the less stable it is.

My goal is really to cut aluminum, but I don’t think this one can do that ever. I could upgrade the spindle to a stronger motor, but even then the Z-carriage is still too weak (guess).

If I want to cut aluminum, I think I really need to build a much stronger one using 4040 or something, and really make a custom stronger Z-carriage. What is this one good for at that point though? I could turn it into a laser engraver / cutter…